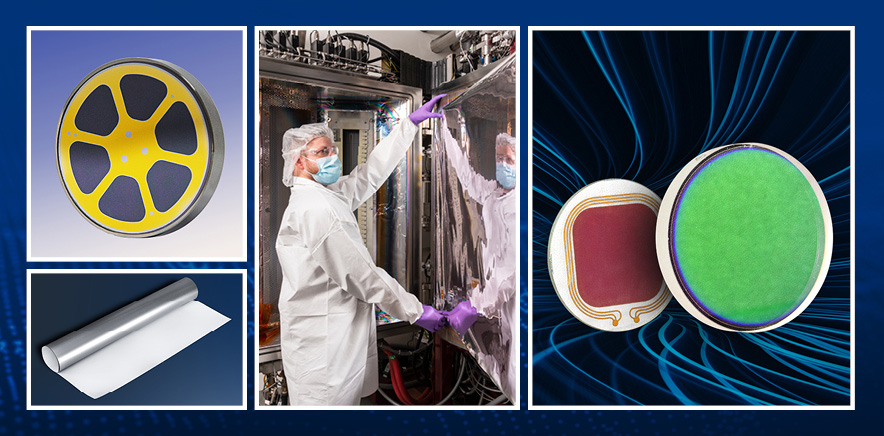

Advanced Materials &

Thin Film Coatings

Deposition Sciences, Inc. (DSI®), a wholly owned subsidiary of Lockheed Martin, is a premier supplier of Advanced Materials and Thin Film Coatings. Located in Santa Rosa, CA, our talented workforce provides the world’s best thin film optical coatings, products and services.

Sunshade

This innovative material reflects solar irradiance and offers ESD protection and RF transmissive performance. It’s designed for use on spacecraft and satellite systems operating in LEO, MEO, GEO, and beyond. Sunshade is available in both free film and tape versions. Sunshade Tape can also be used as a Flexible Solar

Optical Reflector (FOSR). It’s commercial off-the-shelf (COTS), space qualified, and flight proven.

MicroDyn®

Our proprietary MicroDyn® magnetron sputtering technology and photolithography processes provide the backbone for manufacturing durable, high performance thin film coatings in the UV, VIS, NIR, SWIR, MWIR wavelength regions.

Who Do We Serve?

Industries include space, aerospace, aviation, commercial, and military customers. Applications include automotive LIDAR, biomedical, astronomy, military, homeland security, aviation, spacecraft, imaging, and ISR.

Industries include space, aerospace, aviation, commercial, and military customers. Applications include automotive LIDAR, biomedical, astronomy, military, homeland security, aviation, spacecraft, imaging, and ISR.

DSI is ITAR Registered and ISO:9001-2015 certified. We are also Cybersecurity (CMMC) Compliant, adhering to information protection control guidelines.

Need Help?

Are you working on a new design? Our technical staff and engineers are available to assist you. Contact us today to set up an appointment to talk through trade-offs, price drivers, and timelines.

Upcoming Events

Small Satellite Conference - August 11-13, 2025

Small Sat is the premier conference on small satellites. Now being held in Salt Lake City, Utah. Find us at booth #623! Learn more »

International Telemetering Conference - October 20-23, 2025

The International Telemetering Conference is non-profit, industry focused event providing a wide range of telemetry topics important to today, and future, telemetry professionals. Learn more »

Space Tech Expo | Europe - November 18-20, 2025

Space Tech Expo Europe is the premier gathering for space professionals across the continent - the largest B2B space event. Learn more »