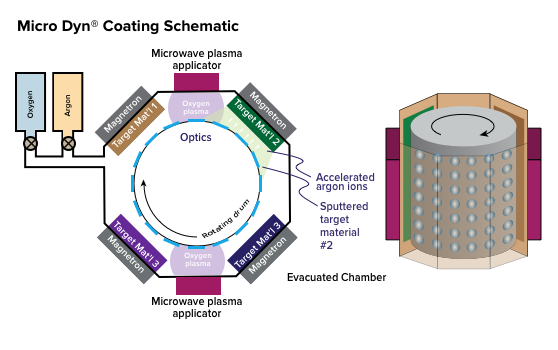

MicroDyn® is DSI’s proprietary version of magnetron sputtering optimized for high throughput. MicroDyn® utilizes an octagonally shaped chamber, where electrically conductive (metal or semiconductor) coating targets are arranged around the periphery, and the parts to be coated are held on a cylindrical rotating drum concentric within the chamber. Unlike other optical coating methods, sputtering does not require heating the coated parts. This allows the technique to be used on a wide range of substrate materials, as well as on assemblies that may incorporate plastic parts.

KEY MicroDyn® ADVANTAGES

- Compatible with a wide range of substrate materials

- Produces dense coatings that are unaffected by temperature and humidity changes

- Enables complex multilayer coatings with sophisticated functionality

TYPICAL MicroDyn® APPLICATIONS

- Cold mirrors

- Absorption Coatings (Dark mirrors)

- Bandpass filters

- Short and long wave pass filters

- Antireflection coatings

- High reflection coatings

- Beamsplitters

- Patterned Filters

In magnetron sputtering, the chamber is first evacuated, and then filled with a low pressure of a sputter gas, typically argon. The targets are biased with a negative voltage and immersed in a magnetic field. Electrons leaving the target are contained in the vicinity due to this magnetic field.

The electrons collide with the sputter gas atoms and ionize them, and these ions are accelerated towards the target(s) because of their negative electrical potential. When these ions impact the target, they cause atoms or molecules to be ejected (sputtered). Due to the low gas pressure, the sputtered particles have a long mean free path length, and they stream away from the source and are deposited on the revolving substrates.

In MicroDyn® sputtering, a small amount of a reactive gas (usually oxygen) is also introduced into the machine during this process and microwaves are utilized to turn it into a plasma. These oxygen ions react with the material deposited on the substrates to create oxides. This reaction is very thorough, yielding oxide layer coatings which have very well controlled index of refraction characteristics. This enhances the ability to accurately achieve the designed spectral performance in the real world coating.

Because the sputtered target atoms are ejected with a large amount of energy, they pack densely into the thin film. The result is that MicroDyn® coatings are inherently harder and less porous than evaporated films. A dense film is advantageous because it doesn’t readily absorb water; this, in turn, makes the coating performance more stable when subjected to large shifts in ambient humidity and temperature. It also means that the film will retain its mechanical integrity through numerous cycles of temperature and humidity. MicroDyn® coatings can also routinely handle exposure of up to 550°C; coatings that can withstand temperatures of up to 1000°C have been produced through a special, patented process.

Another advantage of DSI’s MicroDyn® sputtering process is that more than one sputtering target can be active at once. Co-sputtering two materials (a high index and low index) simultaneously allows the creation of a mixed layer with a controllable intermediate index. This extra degree of freedom gives the coating designer significantly greater flexibility, and enables the production of more sophisticated thin films. The same factors that make MicroDyn® films so thermally and mechanically durable also allow the fabrication of stable films containing very large numbers of layers, which further enhances the designer’s power.

Learn more about the reactive sputtering process with our ebook