Product Overview

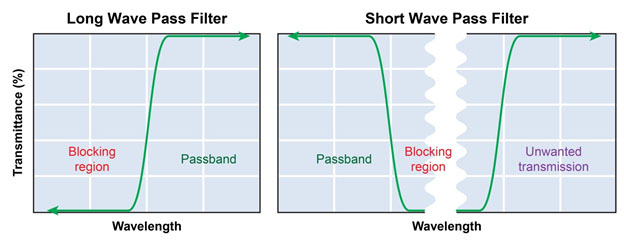

Edge filters, also sometimes called dichroic filters, are coatings that include short-wave pass and mid-wave pass filters. Specifically, these coatings transmit one range of wavelengths while blocking others. However, they are distinct from bandpass and notch filters in that they either pass wavelengths above (mid-wave pass) or below (short-wave pass) a given single wavelength value, rather than a limited band of wavelengths within a range.

The DSI Difference

DSI custom manufactures a wide selection of edge filters for use at wavelengths ranging from ultraviolet through mid-wave infrared. The designs can be optimized for various performance characteristics, including high in-band transmission, strong out-of-band blocking, polarization insensitivity, and sharp transitions between the passband and blocking region. DSI edge filters are distinguished by excellent durability with no wet/dry shift.

Technical Information

DSI’s MicroDyn magnetron sputtering method for the fabrication of edge filters enables us to tailor coating performance, cost, and durability to meet your particular performance specifications and budget.

MicroDyn®: DSI employs this technology to deliver environmentally stable and exceptionally durable coatings from the UV to the mid-wave IR, making it ideal for many aerospace applications. Because MicroDyn deposition can be performed at relatively low temperatures, these edge filter coatings can be applied to a wide range of substrate types, including plastics and temperature-sensitive active devices.

Specifying Cost-Effective Edge Filter Coatings

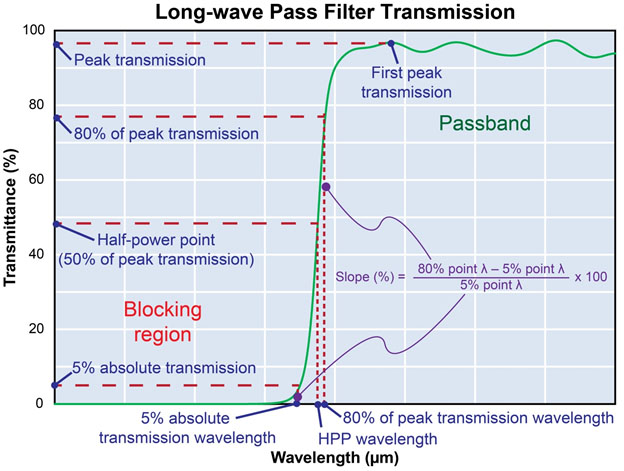

When specifying edge filters, it’s useful to understand some of the most common design and production tradeoffs in order to avoid writing specifications in a way that drives up costs unnecessarily. Some of the key specifications for edge filters are the half-power point (HPP) placement tolerance, slope steepness, and blocking requirements. The graph here shows how these are defined.

Definitions of edge filter performance parameters. The Out-of-Band blocking may be specified to start at the first 1% or 0.1% transmission point, or sometimes at a given wavelength away from the half-power point, or even at a particular wavelength. It may be specified as a maximum value, average value, or total integrated power within the blocking range.

The out-of-band blocking (OBB) is the amount of allowable transmission within the blocking region, which is usually specified to start at the 1% or 0.1% transmission point of the curve, or sometimes at a given wavelength away from the half-power point, or even at a particular wavelength. It may be specified as a maximum value, average value, or total integrated power within the blocking range.

Wavelength (HPP) Accuracy vs. Cost

A half-power point (HPP) tolerance of ±0.5% (of the wavelength value) or higher is relatively routine, while tighter specifications tend to drive up cost.

Slope Steepness vs. Cost

Similarly, slopes of 2% or greater are standard; smaller (steeper) values are more difficult. Thus, if there is a large separation between the wavelengths to be passed and rejected in a system, it’s important not to put arbitrarily tight constraints on these values. While extremely tight tolerances for these values can be achieved by measuring and selecting filters after fabrication, this can become expensive as part size increases, and may not be entirely practical in higher volumes.

Out-of-Band Blocking vs. Cost

High absolute out-of-band blocking specifications (greater than OD3, or <0.1%) are costly because these require “over-designing” the blocking region to ensure there are no possibilities of leaks. In contrast, an equivalent tolerance on average blocking is much easier and less expensive to achieve.

It’s also important to realize that there is a key difference between the blocking characteristics of the typical mid-wave and short-wave pass filters. Specifically, the blocking range on mid-wave pass filters generally extends from the nominal blocking point all the way to X-rays. Similarly, the passband extends to wavelengths at which the substrate or coating materials themselves become opaque. In contrast, the blocking band for shortwave pass filters is usually limited, and the optic eventually begins to transmit again. This is shown in the graphic. Attempts to extend the blocking range farther can compromise transmission in the passband. Thus, if an application requires extended out-of-band blocking, it’s better to design it to utilize mid-wave pass filters, rather than short-wave pass filters, or to incorporate wavelength-specific absorbing substrates into the design in addition to the edge filter coating.

Useful Cost Tip

Achieving very high out-of-band blocking usually requires compromising the in-band transmittance because the very thick blocker coating layers can cause absorption and scatter, and the larger number of layers is more susceptible to tolerance problems during manufacture. Thus, it is important to try to avoid simultaneously specifying both high peak transmittance and strong out-of-band blocking.

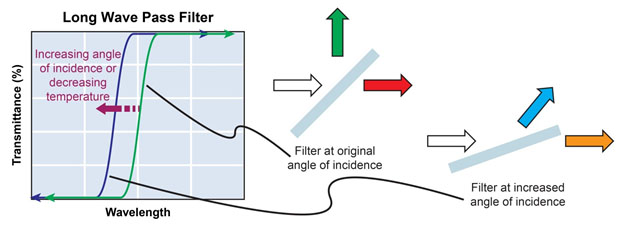

Angle and Temperature Sensitivity

The spectral characteristics of all optical coatings shift to shorter wavelengths as angle of incidence is increased, and/or temperature is decreased, and this can dramatically affect the performance of edge filters. In some cases, this effect can be purposefully employed to enable tuning of the filter’s performance over a limited range of wavelengths.